Mont-Saint-Guibert, June, 2024 – AMIAURA™ is a new solution developed by Ajinomoto thanks to the power of amino-acid technologies. It brings a new way to treat your pigments and powders achieving both functionality and respect for the environment.

Challenges in Make-up formulations

Silicon-free & natural trends.

Today, formulators are facing a dilemma when selecting silicon-treated pigments and powders. Known for their good functionalities, they aren’t trendy anymore following the usage of more and more natural ingredients in makeup. Moreover, silicon-treated powders sometimes oblige the usage of silicon-based dispersing agents due to their limited compatibility with non-silicon oils.

Skinification trend

Humectants used to compensate the drying effect of powders or to give a skin-nourishing benefit to the formulation are often degrading the makeup wear.

The Ajinomoto solution

To tackle the above challenges, we launched the AMIAURA™ kit to treat the powders with the following benefits:

- Silicone-free solution

- High functionality in pressed formulation or emulsions

- Excellent moisturizing effect on the skin

How it works?

Two solutions are simply mixed sequentially with your powders to create an “amino gel” coating the particles.

Benefits:

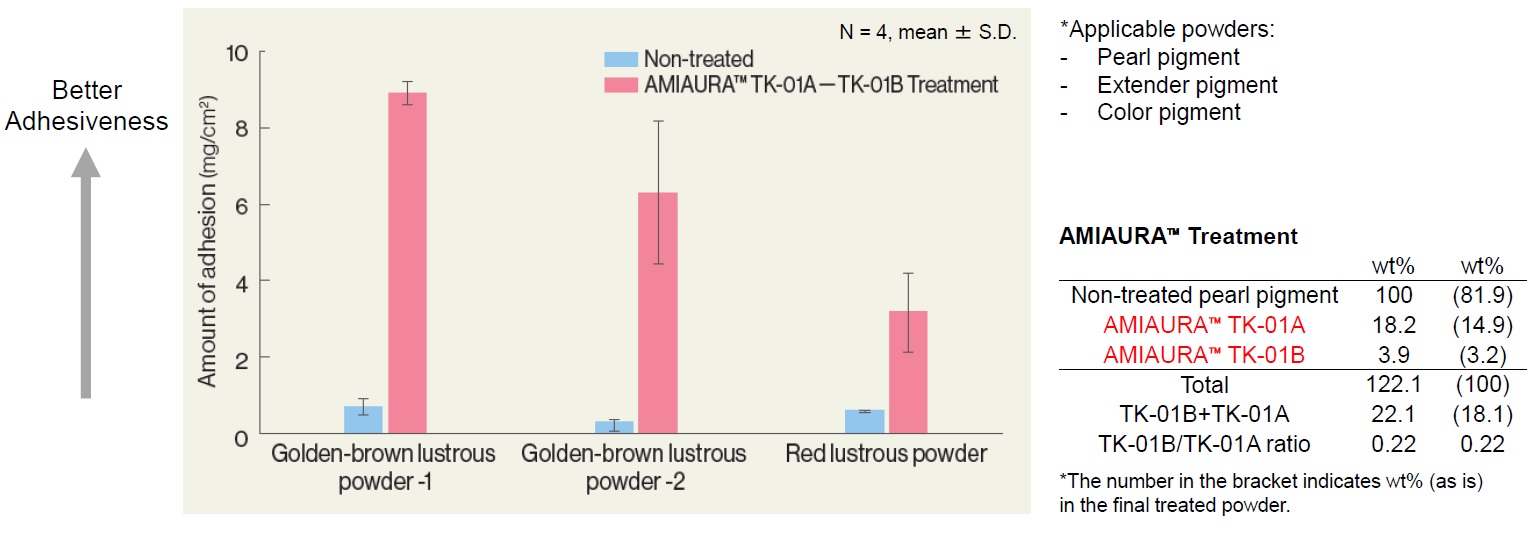

Good skin adhesion

Protocol:

A glass vial containing powder and a piece of cover glass was shaken. The cover glass was removed and weighed, and the powder adhesion was evaluated from the change of the weight.

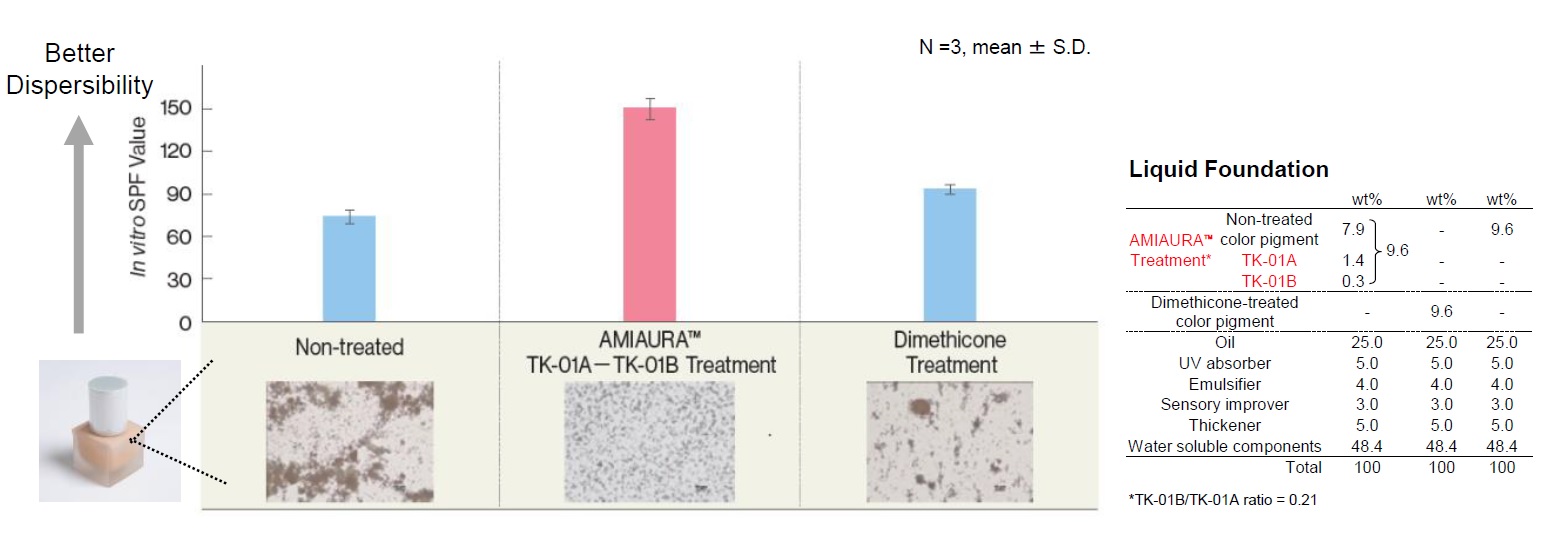

Good dispersibility

Test formulation: W/O liquid foundation containing 9.6% inorganic pigment. TK01A: 1.4% and TK 01B: 0.3% are incorporated In the final formulation. Microscopic observation: Pigment dispersibility of the test sample was observed with a microscope X40 after 1 month of preparation.

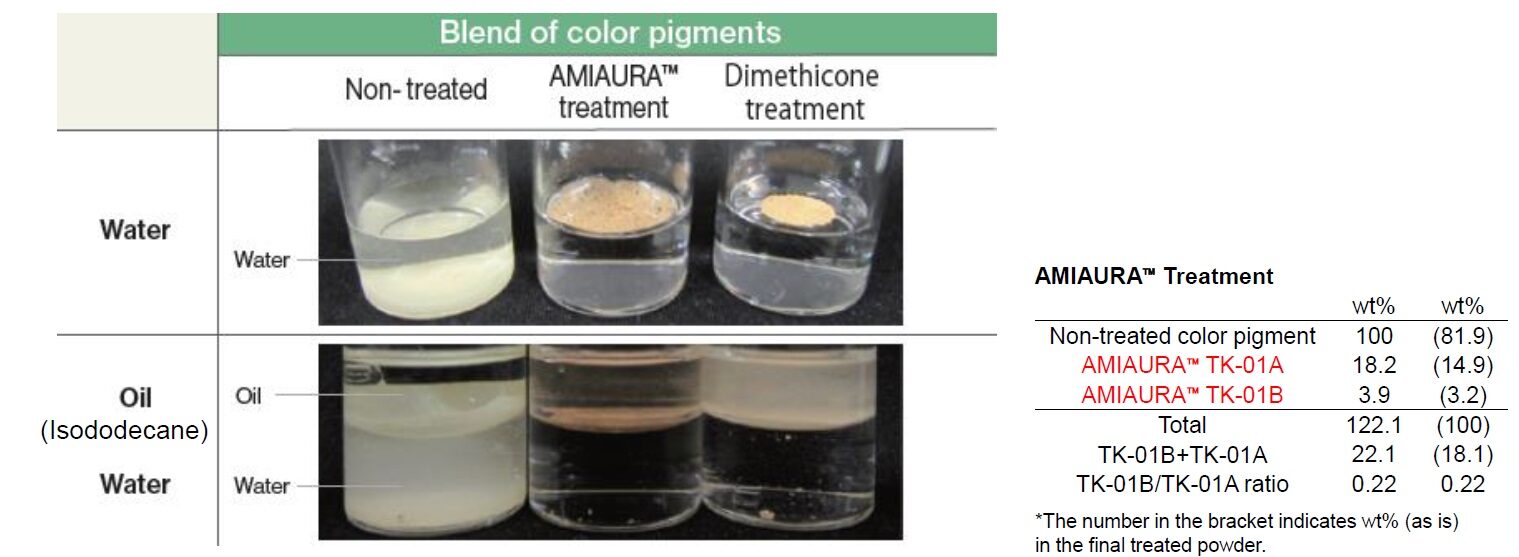

Good hydrophilic/liphophilic balance